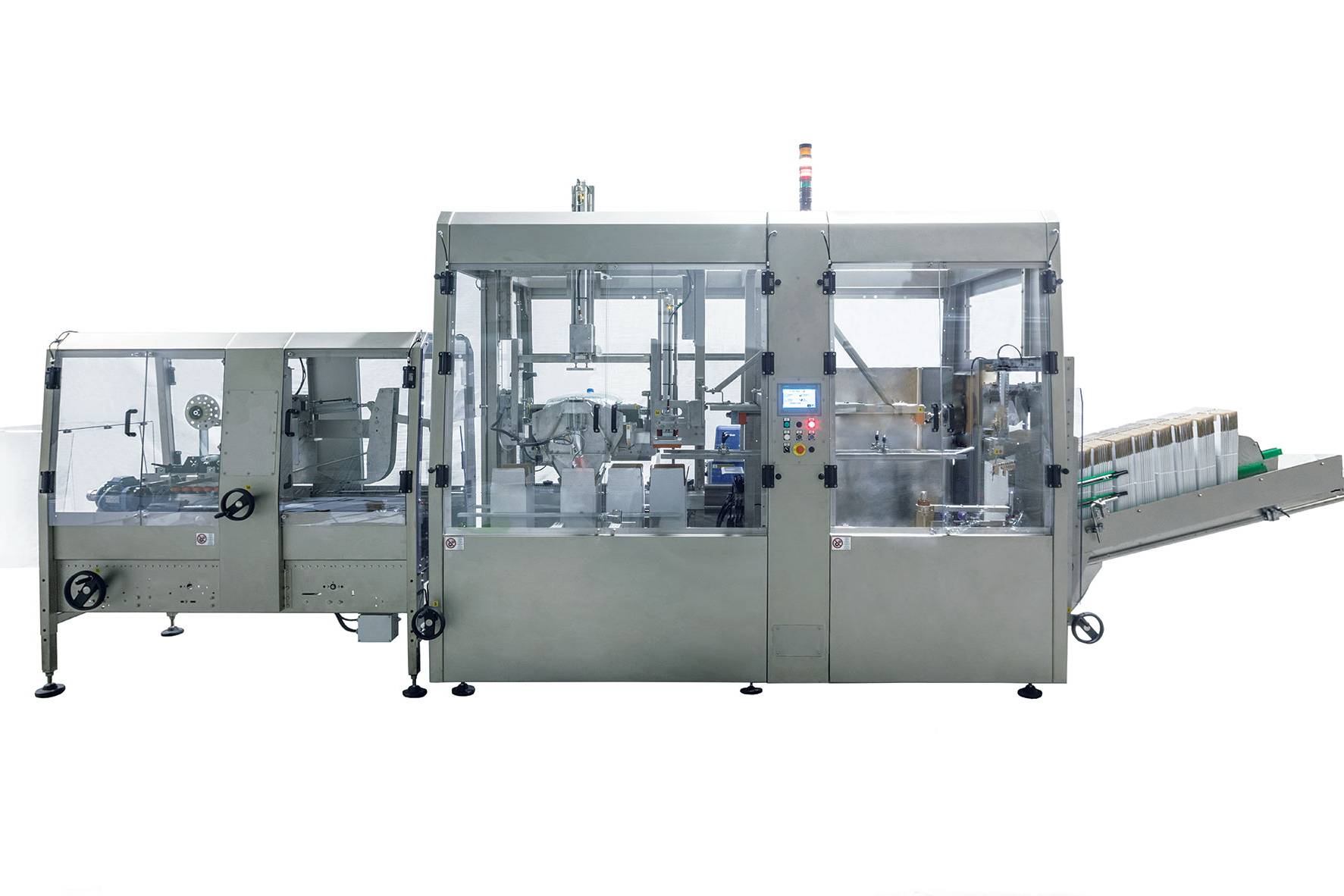

FIPAL Monobloc packaging units are designed and manufactured to combine maximum packaging performance with small operating spaces, combining the carton forming, cartoning and closing phases.

FIPAL Monobloc packaging units are unique and innovative solutions designed to meet the most diverse cartoning requirements of any type of container, from box formation and the insertion of the containers to closure with glue or adhesive tape. These Monobloc packaging units are also designed, with a few simple operations, for a quick format change-over.

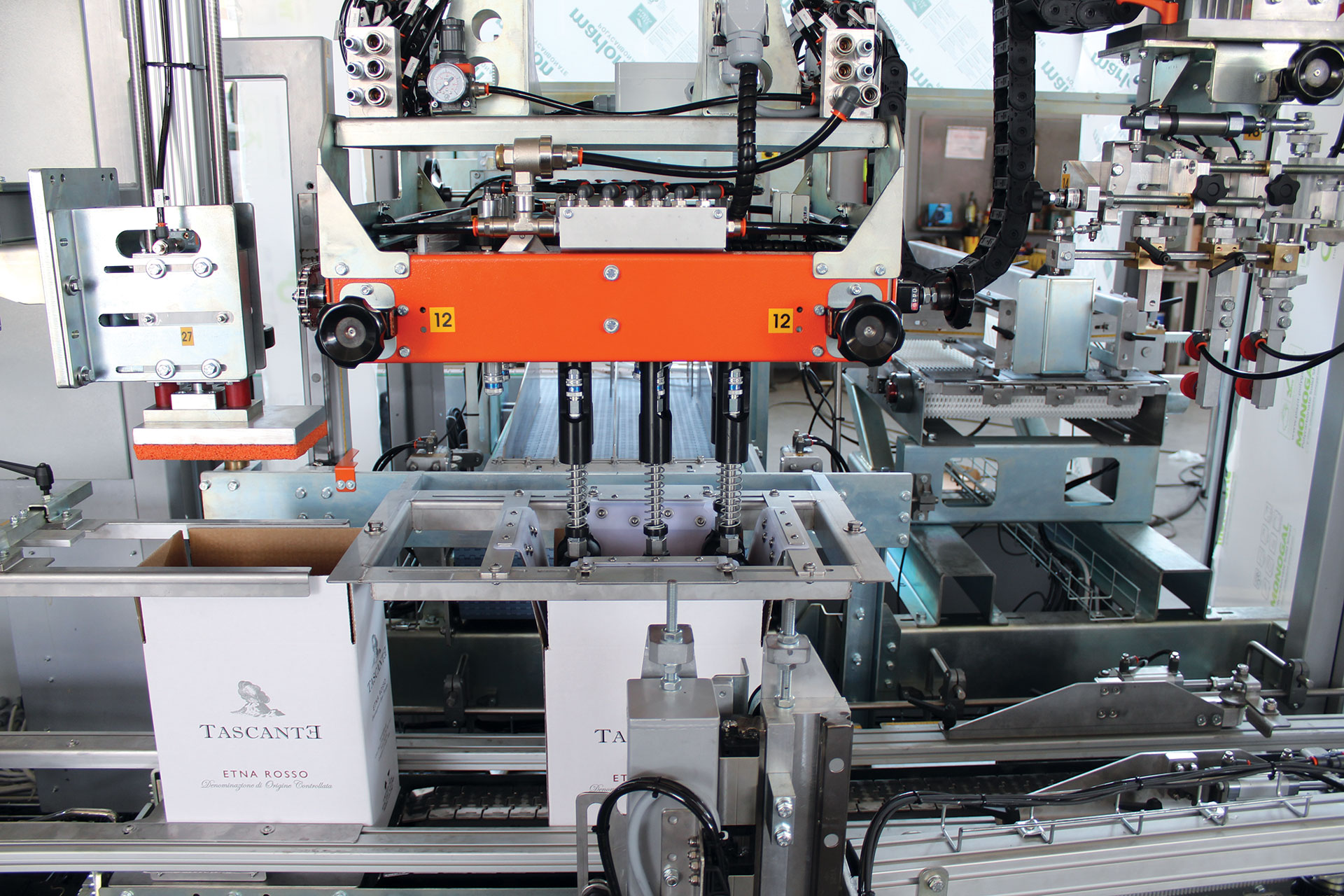

FIPAL can customise the machine to adapt it to the most diverse requirements of the processed product.

FIPAL offers four types of Monobloc packaging units:

- COMBI: completely automatic monobloc able to handle American cardboard type and to work with a wide variety of glass, PET and tinplate products. They can be fitted with one or two gripping heads and box sealing can be carried out with hot-melt glue or PVC tape. Ouput up to 1.000 boxes/h.

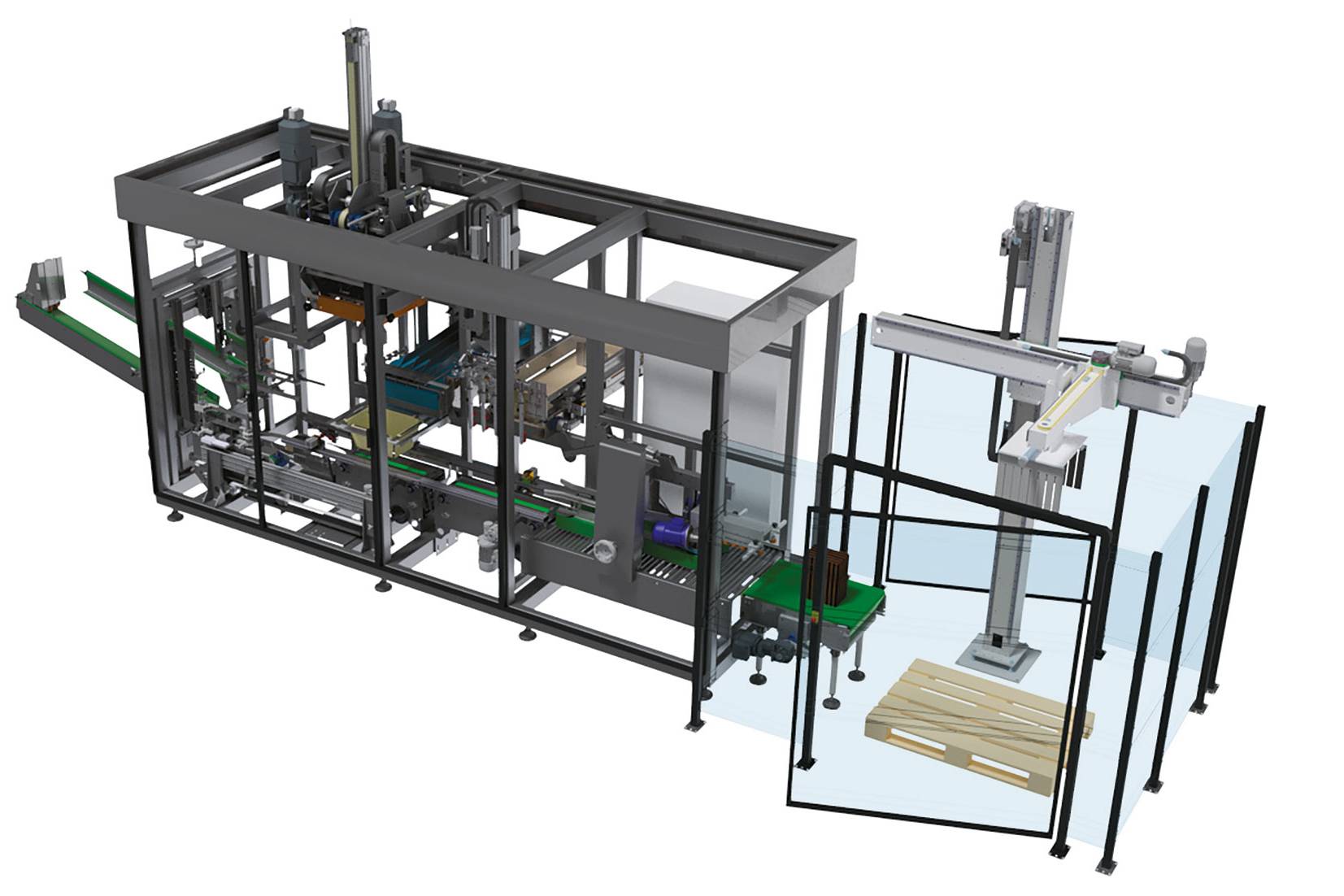

- COMBILINE: Packaging combined machine. Your end of line, compact, reliable and cost-effective. Combined machine for outputs up to 3.000 bottles/hour. Reduced overall dimensions 2,2×7,7 m. There are 6 units which can be integrated to get the complete configuration: Box forming machine, Case packer, Bevel inserter, Box closer, Palletizer, Winder.

- COMBI BUS: designed by following COMBI general technical principle, and hence displaying all the strenghts and technologies already exploited and enhanced. It is specifically developped to pack bag in box packs.

- COMBI MS: additional conveyor that allows to create an even more flexible machine, and especially conceived for all those customers which handle several product types with various packages.

The equipment makes it possible to insert the cardboard partition inside the box.

Fill out the form

Quick response guaranteed!

...or call us

+39 0525 431199

(GTM+2; Italian time)

9,00 > 13,00 | 14,30 > 18,00